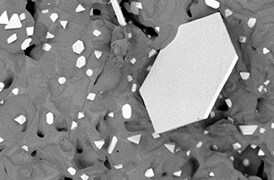

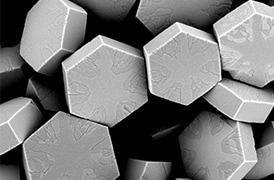

Whether studying new materials or attempting to find the root causes of failures, highly localized characterization of increasingly complex samples with ever-smaller features is becoming increasingly critical. In fact, sub-surface or three-dimensional characterization is often required to fully understand the material properties of a sample. This can be particularly useful for heterogeneous materials or the detection and characterization of inclusions and precipitates. DualBeam (focused ion beam – scanning electron microscopy, FIB-SEM) instrumentation enables the acquisition of high-quality 3D datasets, at nanometer resolution, by serial sectioning (sequential application of SEM imaging and FIB milling).

Plasma FIB (PFIB)

Often, large volumes, which are inaccessible with conventional gallium FIB instruments, are necessary to obtain representative and statistically relevant results due to the additional contextual information a large sample provides. Plasma FIB instruments, such as the Thermo Scientific Helios 5 PFIB DualBeam and the Thermo Scientific Helios Hydra DualBeam, offer excellent high-current performance enabling fully automated, high-quality, large-volume 3D datasets in a variety of modalities. Additionally, the multiple ion source technology of the Helios Hydra DualBeam allows you to choose the best ion source for each particular sample and use case.

Plasma FIB serial sectioning can provide information on materials contrast (with backscattered electron imaging), compositional information (with energy dispersive spectroscopy), and microstructural and crystallographic information (with electron backscatter diffraction). This data can then be visualized with Thermo Scientific Avizo Software, delivering a unique workflow solution for the highest-resolution, advanced 3D characterization and analysis at the nanometer scale.

Laser PFIB

The Thermo Scientific Helios 5 Laser PFIB System goes beyond regular plasma FIB to perform cross-sectioning and 3D characterization of even larger volumes, up to millimeter-scale (with >15,000x faster coarse material removal as compared to gallium FIB). It also facilitates the processing of materials that are typically challenging for ion beam milling, such as charging and beam sensitive materials, with minimal damage.