Automated large volume SIMS analysis

Achieve detailed and extensive analysis with fewer artifacts, enhancing data accuracy and reliability.

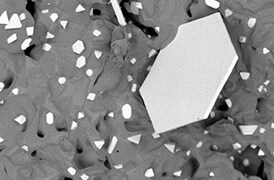

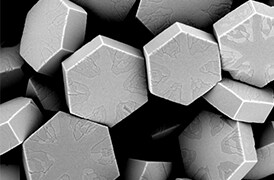

3D SIMS imaging of uneven surfaces

Particularly beneficial for analyzing particle materials, such as battery electrodes, enabling comprehensive characterization.

Optimized geometry for SIMS

Automated functions and image matching for pre-alignment before capturing 3D SIMS data, along with stage rotation and tilting at optimized positions to ensure precision.

Seamless operation

SIMS data acquisition is fully integrated into Auto Slice & View 5 Software, ensuring a smooth and efficient user experience.

With these advancements, 3D SIMS offers outstanding capabilities for researchers and industry professionals, enabling more detailed and accurate analysis of complex materials.